Previous

Next

Call Today for more information

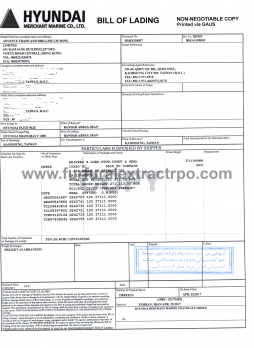

Dubai rubber process oil,rubber processing oil,RPO,Furfurl Extract

Dubai rubber process oil is special furfural extract RPO which can be broadly classified into two different groups (as below) depending on the physical arrangement of the carbon atoms. Paraffinic, aromatics. Rubber Process Oil are used during mixing of rubber compounds. These help in improving the dispersion of fillers and flow characteristics of the compound during further processing. Rubber process oil are specially developed taking into consideration the type of rubber and the end product applications.Rubber extender oil aromatic types

Aromatic process oil well-known according to its viscosity which meet ASTM D-445 and ISO 3104 (American society for testing and materials) Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (Calculation of Dynamic Viscosity) HScode27079900 it has different grades famous as high(heavy) , medium , low(light) viscosity, TDAE and DAE .The primary characteristics of aromatic hydrocarbons are the presence of the double bonded mix ring carbon structure. Aromatic extracts/ rubber process oil (RPO) procured from selected refineries and suitably blended to meet stringent specifications, are used for compounding batches to manufacture Tyres, lactic , automotive tyres and tubes, bi-cycle tyres, tyre re-treading materials, belting, hoses, battery casings and containers, extruded products, technical molded goods and rubber articles with reclaim rubber due to high solvency., calendared and moulded sheets, Tread rubber .also process oil (furfural extract) has a colour stability, solubility and good thermal stability makes RPO ideal for moulded articles, slippers, LPG tubes, floor tiles, etc.Furfural extract oil paraffinic types

Paraffinic process oil well-known according to its viscosity which meet ASTM D-445 and ISO 3104 (American society for testing and materials) Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity) HScode 27079900. This class of hydrocarbons constitutes branched chain or straight linked hydrocarbon molecules of various viscosities. As the chain length increases, the viscosity increases and the rubber process oil (furfural extract RPO) becomes more viscous. They find extensive usage in Butyl rubbers. Paraffinic process oils with high viscosity and high flash point is better shelf life of the end product. Because parrafinic Furfural ekstrakt has higher viscosity and paraffinic content are preferred for achieving high retention of properties after ageing and higher loading of oil in applications like heat resistant / steam hoses and conveyor belts.RPO usage

The process oil is used to facilitate the operation of manufacturing the rubber, such as kneading, extrusion, molding, etc., by means of its property to penetrate into the texture of a rubber polymer.It is also used to improve the physical properties of rubber products. For such process oil, it is necessary to have suitable affinity for rubber. On the other hand, the rubber to be processed can be classified into natural rubber and synthetic rubber, and there are many types of synthetic rubber.How to get rubber oil

To prepare this rubber process oil, use is made of a lubricant fraction obtained by distillation of crude oil under reduced pressure; an oil which is obtained by deasphalting residues distilled under reduced pressure, subjecting as necessary to dewaxing treatment and hydrogenation refining treatment, and further subjecting to sulfuric acid refining treatment; or an extract which is obtained by extraction treatment of oil with a solvent having an affinity for aromatic hydrocarbons. Thus obtained rubber process oil contains 70 to 99% aromatics as determined by column chromatography, has a % CA value of 20 to 50% as determined by ring analysis according to the Kurtz method, and contains 5 to 25% by mass of extracted matter with dimethylsulfoxide (DMSO) which corresponds to a content of polycyclic aromatics (PCAs) according to the standards of The Institute of Petroleum.Quality of Dubai rubber process oil

Our firm offers Inspection services for any kind of process oil , rubber oil, aromatic rpo , paraffinic rpo , Crude Oil – Hydrocarbon Content oil – Liquid Chromatography oil- Organic Matter Content – Petroleum Oils – Rubber Extender Oils – Rubber Processing Oils , Dynamic Viscosity – Glass Capillary Viscometers – Kinematic Viscosity – Liquid Petroleum Products – Petroleum Products , furfural, furan carboxaldehyde, fural, furfuraldehyde, furaldehyde, pyromucic aldehyde , Furan carbaldehyde and approval on all our deals and contracts. any third party inspection is crucial if you don’t know your supplier or if you are not very expert in the field you are trading or purchasing a product.OUR CLIENTS